-

Meicun Road, Meilin, Futian District, Shenzhen, Guangdong, China

Perfume Boxes Wholesale Near Me

Perfume boxes wholesale near me: choose Lid and Base Boxes with inserts, foil, and strict QC. OEM/ODM for brands, traders, and startups. Pearl or glitter wraps, neck & shoulder builds, FSC materials, clear PP sampling to mass. Fast lead time, stable color, and simple comms for smooth launches.

You typed “perfume boxes wholesale near me” because you want fast samples, clean print, and a supplier who actually picks up the phone. Good call. Let’s walk through what to check, how local vs. overseas plays out, and where Lid and Base Boxes (rigid set-up boxes) fit for real-world use—without fluffy talk. I’ll keep it simple, practical, and a bit chatty (some tiny grammar slips too, no biggie).

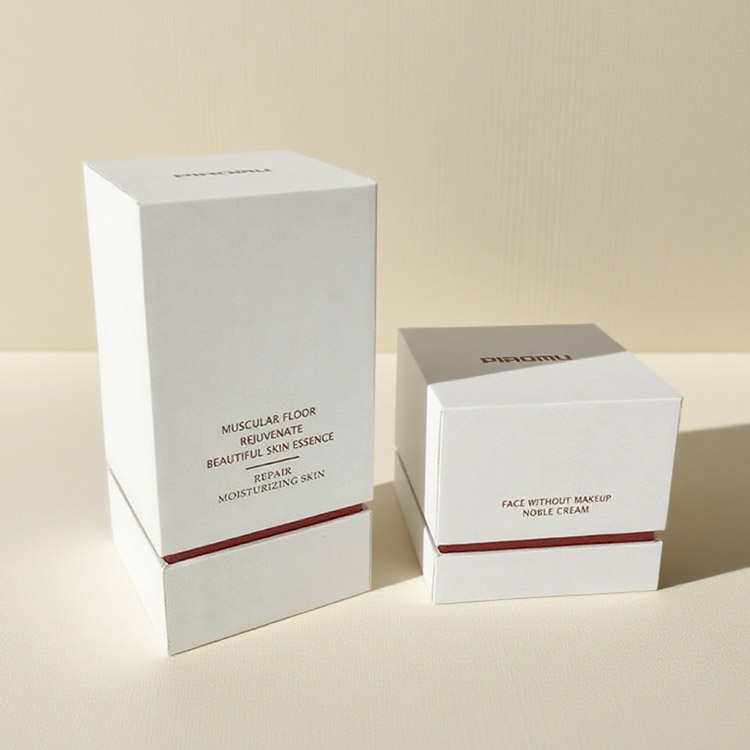

Lid and Base Boxes

Rigid Lid and Base Boxes nail the “giftable” look and protect glass bottles on the shelf and on the road. They pair well with neck & shoulder structures, hot foil, and premium papers (pearl, glitter, fine art). If you want a quick feel for specs and sizing logic, check your die-line early and lock the CMF (color–material–finish) before you quote. btw, PANTONE matching saves headaches.

Explore examples:

- Lid and Base Boxes

- Pearl Paper Perfume Packaging Lid and Base Boxes Supplier

- Red Neck Shoulder Lid and Base Perfume Boxes Wholesale

- Versace Eros Perfume Red Hot Stamp Foil Lid and Base Boxes

Perfume boxes wholesale near me: what actually matters

Local often wins on speed and comms. Overseas often wins on scale and deep finishing menus. Don’t overthink it—map your needs, then pick the lane.

Decision factors for “near me” searches (table)

| Factor | Why it matters | What good looks like | Source |

|---|---|---|---|

| Lead time | Launch windows move fast; delays kill margin | Clear production calendar, buffer before ship | Supplier SLA; internal ops norms |

| MOQ | Small brands can’t sit on big stock | Tiered price breaks; pilot run possible | Industry practice; buyer guides |

| Print & finish | Shelf appeal is everything | Hot foil, emboss/deboss, spot UV, soft-touch | Packaging finishing standards |

| Inserts | Reduce bottle rattle & breakage | EVA, paper pulp, or foam with tight tolerances | ISTA handling basics |

| Compliance | Avoid relabeling or platform rejections | Ingredients panel on outer box; IFRA-friendly | EC 1223/2009; IFRA Code of Practice |

| Sustainability | Buyers ask for it, retailers too | FSC materials; recyclable or recycled options | FSC Chain of Custody guidance |

| QC | Catch issues before freight | AQL-based inspection; color delta checks | AQL sampling; print QC playbooks |

Neck Shoulder Lid and Base Boxes (use case heavy)

Neck & shoulder builds add that stepped reveal when the lid lifts—premium vibe, better rigidity. You’ll see it on gift sets, limited drops, and holiday kits. If your bottle is tall or has an odd geometry, a custom insert + neck & shoulder keeps it centered and safe in transit. It do matter for glass.

Typical pitfalls:

- Loose inserts (micro-movement = scuffs).

- Over-embossed logos that crack on corners.

- No crease allowance in the lid (lid sits proud, looks off).

Pearl Paper Perfume Packaging (when you need instant “lux”)

Pearl papers catch light and hide tiny scuffs. They’re great for pale colorways and wedding-style launches. Mind ink holdout: do a quick drawdown to test coverage—pearl stock can change perceived hue vs. coated white. For gentle glam plus protection, pair pearl wrap + gold foil + soft-touch lamination. Kinda classic, still sells.

Red Hot Stamp Foil for Perfume Boxes

Red foil hits hard for festive or nightlife SKUs. Pair with matte lamination so the foil pops without glare wars. Keep foil area reasonable—large solid foil fields can show micro-press marks. Use a crisp brass die, and ask for make-ready sheets to check pressure. If you see halo, dial it down.

MOQ and lead time for perfume boxes wholesale

You’ll hear “low MOQ” a lot. Translate that to “can we test a small batch without weird surcharges, and can they repeat it?” For timing, split your plan into 3 blocks: sampling → pre-production (PP) → mass. Don’t skip PP; it catches color drift, foil density, and fit of the insert to the bottle shoulder. Quick tip: book capacity early around holidays—everyone’s chasing slots.

Materials, finishes, and inserts (quick cheat sheet)

| Item | Options | When to pick | Source |

|---|---|---|---|

| Board | Greyboard with wrapped art paper | Core structure for rigid boxes | Rigid box norms |

| Wrap paper | Pearl, glitter, specialty uncoated, coated | Different tactility and light play | Supplier swatch books |

| Lamination | Matte, gloss, soft-touch | Scratch resistance & feel | Converting practice |

| Decoration | Hot foil, emboss/deboss, spot UV | Brand cues & shelf pop | Finishing handbooks |

| Insert | EVA, EPE, paper pulp, corrugate | Shock absorption, sustainability goals | ISTA 3A style testing notes |

| Certification | FSC | Retail compliance & brand claims | FSC standards |

| Labeling | Ingredients list on outer box | EU/UK retail; platform rules | EC 1223/2009; IFRA COP |

Perfume-box: OEM/ODM for brand owners and traders

perfume-box focuses on OEM/ODM luxury rigid packaging—think Magnetic Closure, Clamshell, Collapsible, Lid and Base Boxes, Shoulder & Neck, Paper Drawer, Tubes, Double Side Open, Heart Shaped, Irregular, Colored Corrugated, Folding Carton, and Paper Gift Bags. If you handle procurement for a major fragrance house, a growing indie label, or a packaging trader, you want repeatability: stable CMF, tight die-line control, and QC that doesn’t fall over when volume spikes. That’s the boring part that saves launches.

Real-world scenarios (not theory)

- DTC launch with small batch: choose Lid and Base Boxes with paper-pulp insert to keep sustainability claims clean; lock two colorways and one foil. Use PP sample to freeze CMF.

- Travel retail or gift set: go Neck Shoulder Lid and Base Boxes for unboxing drama; add a ribbon pull or finger notch for easy lid lift; tolerance on shoulder height is key.

- Nightlife SKU refresh: run Red Hot Stamp Foil on a matte black wrap; tiny spot UV on brand mark adds depth without shouting; check rub resistance on corners.

- Sampler program: slim rigid or mini drawer box; EVA cavities sized to rollerball diameter; keep board caliper light to reduce freight, but don’t go flimsy.

Quality control and AQL (keep it simple)

Ask for AQL sampling with photo reports. Have them check: lid sit (no proud edges), corner wrap (no wrinkles), foil registration, and insert snugness. A small pre-ship audit beats returns later. Not gonna lie, it’s boring. It works.

Compliance and labeling (don’t skip)

For EU/UK retail, list Ingredients on the outer box where buyers can read it. Align fragrance safety with IFRA guidance. If you use glass with decorative paints, ensure heavy-metal limits meet applicable norms. Keep the paperwork handy; some platforms will ask.

Source notes: EC 1223/2009 (cosmetics labeling), IFRA Code of Practice (fragrance safety), FSC Chain of Custody (paper claims), common ISTA handling guidance for packaging durability.

Pricing logic without the math

No need to drop numbers here. Just remember what moves your unit cost: board grade, wrap stock, surface treatments, structure complexity, insert type, freight mode, and your order size. Lock the design first, then ask for a matrix quote across finishes and quantities. You’ll see the pattern quick.

Where Lid and Base Boxes shine

When you want a premium face with reliable protection and simple kitting, Lid and Base Boxes are the workhorse. You can push them luxe with pearl or glitter wraps, or keep them clean with soft-touch + blind deboss. If you need quick inspo, also peek: Victoria Secret Perfume Scent Lid and Base Boxes Set Factory.

Why “near me” isn’t the only filter

Proximity helps with sampling and comms. But the right shop—one used to OEM/ODM volume, color control, and complex finishes—often saves time even if they’re not next door. If they hold FSC certs, manage AQL, and know perfume inserts cold, you’re already ahead.

Mini checklist before you brief a supplier

- Final bottle drawing with tolerances

- Target CMF and finish hierarchy (foil vs. emboss priority)

- Insert choice (EVA / pulp / paperboard) and drop tests target

- Labeling copy incl. Ingredients if needed

- Sample timeline → PP → mass plan

- QC points (lid fit, corners, foil density, color delta)

Who is this for

- Big brand procurement teams needing locked specs and scale

- Indie perfume founders who want small runs that can grow later

- Packaging traders and distributors managing multiple SKUs fast

- Private label departments and contract manufacturers