-

Meicun Road, Meilin, Futian District, Shenzhen, Guangdong, China

Custom Perfume Boxes Manufacturing for Wholesalers: A Practical Guide to Success

Wholesale fragrance packaging that looks premium and ships safe. perfume-box builds magnetic closure rigid and foldable boxes with EVA, foil, emboss, spot UV. OEM/ODM, FSC options, AQL QC, golden sample control. Simple workflow, fast launch, clean color, steady quality from proof to pallet.

You sell scent. The box sells the story. If you run wholesale, you need a box that protects glass, looks premium on shelf, and won’t break the lane on cost. Below is a straight-talk guide that folds real factory flow with on-the-ground tips. It’s written for buyers, brand owners, and packaging traders who want repeatable results with OEM/ODM at scale.

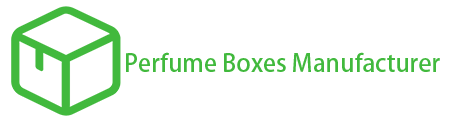

Magnetic Closure Boxes for Luxury Fragrance Packaging

Magnetic closure rigid boxes hit that sweet spot: classy feel, solid protection, easy open-close. They’re a go-to for gift sets and high-end SKUs. See the Magnetic Closure Boxes lineup on perfume-box for styles and finishes that scale well in wholesale runs: Magnetic Closure Boxes

When Magnetic Closure Boxes Make Sense (and when they don’t)

- You want “box as product” vibes: a strong unboxing moment, rigid walls, audible click.

- You need EVA or foam inlay to lock a fragile bottle.

- You run color-critical branding or foil accents that need tight registration.

- Don’t use them when logistics are super tight on weight, or when you need ultra low unit cost with barebones features. A foldable rigid could be a better play.

Custom Perfume Boxes Manufacturing: Structure, Materials, Finishes

Start with structure, not artwork. Lock dieline first, then CMF (color, material, finish). Magnetic rigid, lid-and-base, collapsible rigid, and folding carton each tells a different story.

Quick matrix (decision at a glance)

| Structure Type | Best For | Shelf Appeal | Shipping & Storage | Notes |

|---|---|---|---|---|

| Magnetic Closure Rigid | Premium SKUs, gift sets | High | Bulkier | Hidden magnets, sharp edges, strong brand feel |

| Collapsible Rigid | E-com + retail mix | High | Flat-pack saves space | Needs strong board + precise tape/glue |

| Lid & Base (Shoulder/Neck) | Heritage/luxury lines | Very high | Bulkier | Great for heavy bottles, layered unboxing |

| Folding Carton | Value lines, testers | Moderate | Light & efficient | Shorter lead, flexible runs |

For magnetic sets with protective foam, check a real combo here: Bespoke Perfume White Magnetic Closure Boxes Sets with EVA

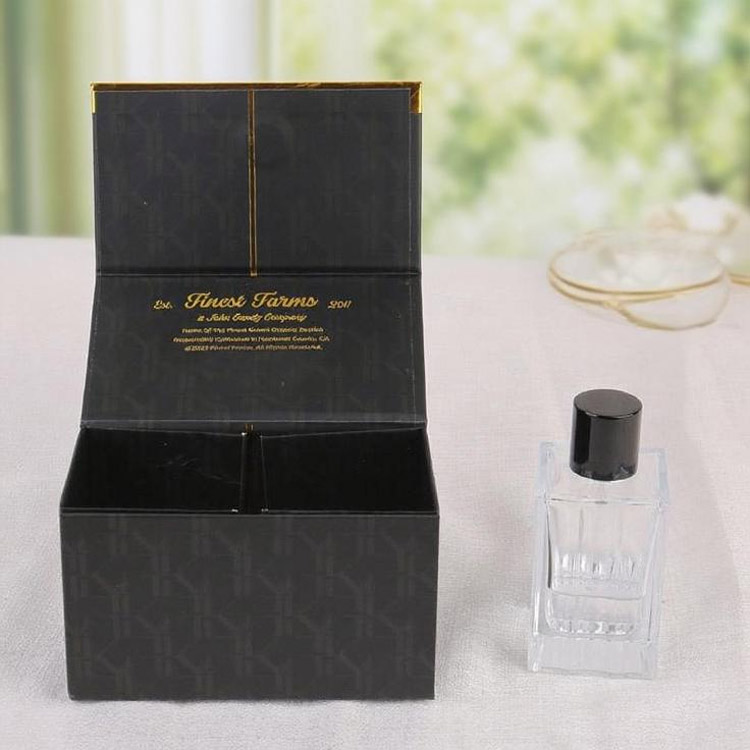

Inner Trays & Protection: EVA, Paper Pulp, Fabric

Inner trays do the real work. EVA foam gives precise fit and shock absorption. Paper pulp trays help with eco goals and can be color-matched. Fabric-wrapped boards signal luxury. For visibility, windows can tease the bottle without opening. Example SKU with a window cut-out: Colorful Perfume Magnetic Closure Lid Boxes OEM with Window

Tray choices (what to pick and why)

| Tray Material | Protection | Look & Feel | Use Case |

|---|---|---|---|

| EVA Foam | High | Clean, premium | Gift sets, heavy glass, travel retail |

| Paper Pulp | Medium | Natural, eco-lean | Sustainability targets, earthy brands |

| Velvet/Fabric Wrapped | Medium | Luxury touch | Limited editions, collabs |

| PET/PVC Clear | Medium | Product on show | Mass retail, “see-before-buy” |

Finishing Techniques for Fragrance Boxes (Foil, Emboss, Spot UV)

Finishes push perceived value. Keep it simple but bold:

- Hot foil for logo hits (small areas > big coverage).

- Emboss/deboss for tactile branding.

- Soft-touch/velvet lamination for hand feel.

- Spot UV to draw light to key elements.

- Holographic paper when you want drama (use on sleeves or accents, not full panel overkill).

OEM/ODM Perfume Box Production Workflow

Here’s the flow most teams run. This isn’t theory; it’s what keeps PO to shipdate clean.

- Dieline & spec: lock final size, board caliper, magnet position, tray type, and tolerance.

- Pre-press: color mode, trapping, overprint, foil plates, varnish masks.

- Color proof: get LAB values or Pantone refs; freeze “OK-to-Print”.

- Golden sample (PP sample): the benchmark. All mass goods match this.

- Run & post-press: print → lamination → foil → emboss → die-cut → glue → tray fit.

- QC & AQL: apply a clear sampling plan (General II is common), with C=0 mindset for critical.

- Cartonization & ship test: set master carton spec, do drop/transport checks, then book freight.

Small note: some buyers skip the golden sample to save time—please don’t. You save days now, you lose weeks later.

Wholesale Perfume Packaging MOQ and Lead Time (Buyer Reality)

MOQ depends on structure, finishes, and tray type. Rigid magnets and multi-pass finishes usually push MOQs higher than folding cartons. Timelines flex with season and process. Simple jobs: weeks. Complex builds with foil/emboss + EVA: more weeks. Lock artwork early, or the schedule slip, it will.

Planning cheat-sheet

| Topic | What to Confirm | Why It Matters |

|---|---|---|

| MOQ Tiers | Unit breaks by structure/finish | Forecast cash flow and inventory turns |

| Critical Path | Material lead, post-press slots | Avoid peak-season bottlenecks |

| Color Standard | Pantone/LAB, print profile | Avoid reprints from color drift |

| Golden Sample Sign-off | One source of truth | Zero debate during QC |

| Shipping Plan | Flat-pack vs assembled | Reduce cube, cut damages |

AQL Inspection ANSI/ASQ Z1.4 for Perfume Boxes

Quality doesn’t happen at the end. Use ANSI/ASQ Z1.4 AQL (also known as ISO 2859-1) for sampling. Set clear defect defs: Critical (safety/fit), Major (functional/visual obvious), Minor (small cosmetic). Pick General Inspection Level (I/II/III), define acceptance, record results. Add C=0 on critical items like magnet alignment, lid gap, and bottle fit. If a lot fails, rework or re-inspect based on your contract. This sound boring, but it’s how you protect margin and brand trust.

FSC Certified Packaging & Sustainability Signals

Many retailers ask for FSC and chain-of-custody proof. FSC board plus pulp trays helps you hit sustainability KPIs without killing the premium vibe. Use claims correctly on pack and on documentation. Buyers do check.

Cost Levers Without Killing the Look

No need to slash quality. Pull the right levers:

- Right-size the box (de-air the void).

- Reduce passes (one foil instead of two; spot UV only where eye lands).

- Rationalize materials (same board across SKUs).

- Switch to foldable rigid if you need space-saving in 3PL.

- Bundle POs for better slotting.

- Artwork hygiene to avoid make-ready waste.

A real-world foldable rigid ref (space saving + luxury feel) you can benchmark: Louis Vuitton Foldable Perfume Gift Rigid Boxes OEM

Real Scenarios (wholesale lens)

- New brand, small line, fast launch: pick a foldable rigid or simple magnetic with one foil hit and EVA. Keep SKUs tight. Freeze color fast. You go live quicker.

- Retail + e-com split: magnetic for retail box, plus a fit-to-ship mailer or sleeve for online. Same dieline, different outer.

- Holiday peak: pre-book post-press (foil/emboss) weeks ahead. It’s the bottleneck.

- Travel retail gift sets: dual-cavity EVA, lid window to show bottle silhouette, top-loading master carton for quick shelf-in.

- Private label: keep a standard magnetic shell and change sleeves only. Speedy demand response with minimal tooling.

Why perfume-box works for OEM/ODM buyers

- Scale & experience: 39-year track record with large daily capacity, so big drops don’t scare the line.

- Magnetic closure mastery: consistent magnet force and clean lid gap, run to run.

- Color discipline: your “OK-to-Print” gets honored on press, less drift, less rework.

- Tray options: EVA, pulp, fabric—plug into your protection targets and CO2 goals.

- QC routine: AQL baked into SOP, with golden sample binding.

- Support: dieline help, pre-press checks, and fast sampling. It’s simple: you brief, they build, you ship.

Sources & Standards (for credibility)

Industry references widely used by buyers and auditors: ANSI/ASQ Z1.4 AQL (ISO 2859-1) for sampling, FSC Chain of Custody for paper traceability, EU CLP & cosmetics label rules for on-pack compliance. Keep these in your spec pack and PO terms.

Internal Data Table (talking points you can paste into your RFQ)

| Key Point | Buyer Action | QC Focus |

|---|---|---|

| Magnetic Closure Boxes | Confirm magnet spec + polarity map | Lid alignment, magnet seating |

| EVA Tray or Pulp Tray | Drop and shake tests with bottle | Cavity fit, deformation |

| Foil/Emboss/Spot UV | Limit passes; prioritize hotspots | Registration, foil adhesion |

| Golden Sample | Make it binding in contract | Compare production against PP sample |

| AQL Plan | Define level and defect class | Record findings, C=0 for critical |

| FSC Board | Request CoC docs | Claim accuracy on pack |